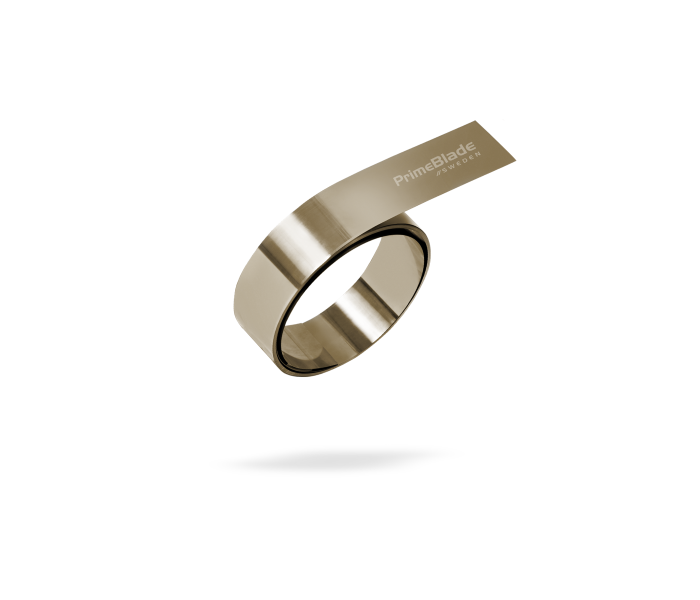

PrimeBlade NANO I

PrimeBlade NANO I

PrimeBlade 900 Nano I has been developed together with partners in Nano technology, to treat and produce different steel qualities to optimise performance.

PrimeBlade 900 Nano I is produced by using the latest Nano technology, with the idea of not using the ceramic & nickel coatings that are used today, resulting in none of the side effects these coatings can have on environment, brittleness and other issues. It´s a revolutionary patented metallurgic-treated steel blade which will extend blade life to hitherto unseen levels in non-ceramic coated blades in both flexo and gravure applications. The blade will outlast any non-ceramic blade on the market, without any of the brittleness associated with long life blades, with no extra consequent anilox roll/gravure cylinder wear and at a competitive price.

Today many flexible packaging printers are looking for solutions that will improve the financial bottom line by increasing productivity, print quality and reducing the downtime due to the lack of blade longevity. PrimeBlade Nano I will be a part of that solution.

| Material | Special Treated Refined Carbon Steel |

|---|---|

| Manufacturer | PrimeBlade |

PrimeBlade® Type 900 Nano II advantages

- High quality genuine Swedish steel

- Long life wear resistance

- Perfect with abrasive inks, such as white inks etc.

- Less adjustment of the doctor blade chamber

- Because of the very small carbides, it breaks down into much smaller particles.

- Anilox roll friction reduced by 40-60%

- High print quality, gives a cleaner wipe

- No ceramic particles involved

- Less particles sticking to the blade

- Thickness: 0.076 mm to 0.50mm

- Edge profiles: Round, bevel, lamella and hybrid

- Straightness: 1,0 mm/3000 mm

- Hardness: 850 HV (top surface only)