Manchester based specialist extruder, flexographic printer and converter Duo Plastics had been using a variety of double diaphragm and centrifugal pumps on their flexo presses for a number of years. Faced with having to carry an ever-increasing number of spare parts for a growing range of models Print Manager, Frank Taylor decided he needed to source a reliable, affordable alternative, which would cover most of his pumping requirements.

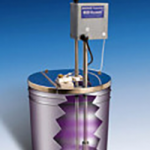

The Internet led him to Wigan-based Advanced Supplies who market the Liquid Flow range of pumps from AB Kelva of Sweden. The Liquid Flow pump is unique due to a number of key design features and, unlike a conventional double diaphragm pump, is ‘stall-proof’ and has a very low pulsation making it ideally suited to printing with doctor blade chambers. What also appealed to Frank was the very small number of parts used to make the LF pump which meant the likelihood of having to carry fewer spare parts and also the fact that the diaphragms can last 4 or 5 times longer than those of conventional DD pumps.

Having initially bought one Liquid Flow pump for trial on his 6-colour OFEM CI press, Frank has gone on to buy further units. “We print solvent-based flexo in up to 6 colours and produce a large range of high quality bags for a wide variety of uses. Reliability is key when it comes to choosing pumps and the LF pump suits our needs for a number of reasons, not least because it allows us to utilise the press more efficiently by minimising downtime as a result of things such as stalling, diaphragm failures etc”

The Liquid Flow pump is available in 4 sizes from 15 litres per minute up to 120 litres per minute and is suitable for virtually any liquid.